Manufacturing has evolved

It is more automated, data driven and dynamic.

To remain competitive, manufacturers need more than production performance analytics, they need a complete Industry 4.0 Smart Manufacturing System that can adapt to their operating culture, reduce complexity and optimize production without requiring expensive capital equipment investments.

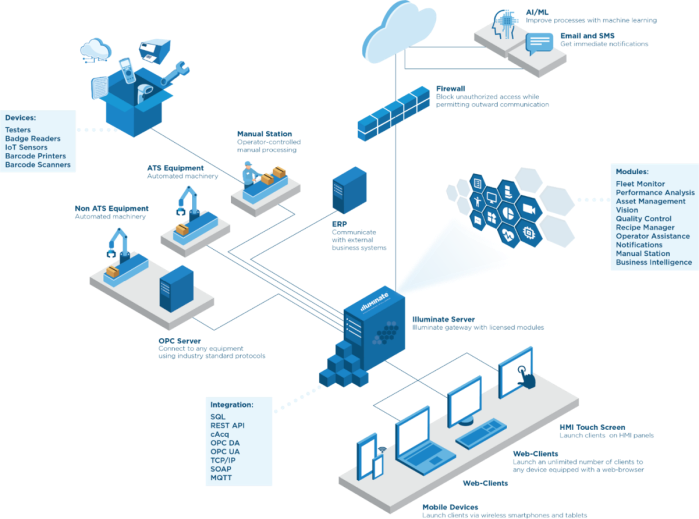

Illuminate™ Manufacturing Intelligence is an extensible architecture used by global leading manufacturers to enhance production visibility and improve operational performance.

“It is the best MES system I have had the chance to implement. It is very user friendly and captures everything

we need. It is also very flexible and able to adopt our constant changing needs and requirements.”

– Customer Testimonial

Visit Illuminatemi.com for more information about Illuminate™ Manufacturing Intelligence

Industry 4.0 Smart Manufacturing System

developed by machine builders for machine operators

Single pane of glass – Monitor operations anytime and anywhere from our turnkey, integrated, and secure single-point platform

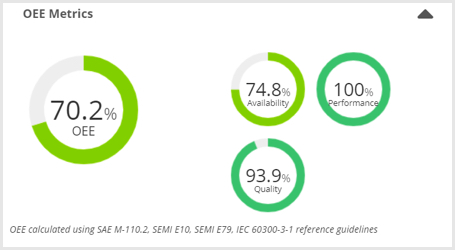

OEE in real-time – Capture real-time OEE intelligence across lines, machines, and locations for top down, bottom up continuous improvement

Visual KPIs – At-a-glance insight with dynamic charts & graphs of key data and metrics

Predictive maintenance – Improve equipment efficiency, yield, and lifespan through AI-driven predictive maintenance

Faster response times – Real-time notifications and alerts enable quicker corrective action

Unified communication – Keep operational team informed and engaged across shifts and locations

Part traceability – Track all components and their associated processes for each of your products through assembly and record it for process analysis, record keeping and compliance

Improve Your Manufacturing Operations

Illuminate™ Manufacturing Intelligence uses real-time machine performance data to maximize throughput, Increase uptime, decrease cost and improve quality.

| Maximize Throughput |

|

| Increase Uptime |

|

| Decrease Cost |

|

| Improve Quality |

|

Visit Illuminatemi.com for more information about Illuminate™ Manufacturing Intelligence