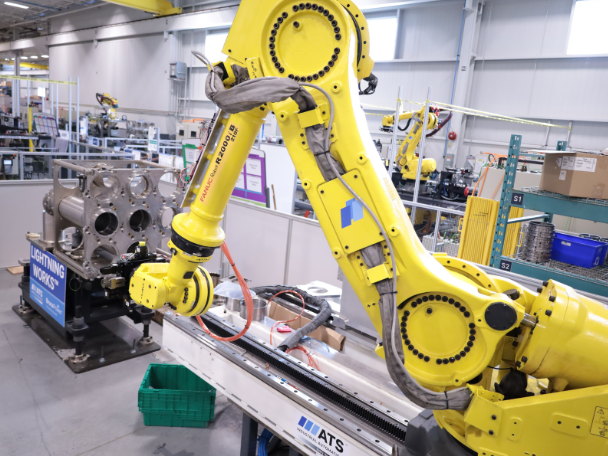

Small modular reactors (SMRs) offer safer, more flexible carbon-free energy. Our nuclear experts work with leading SMR companies to design, build, and test automated solutions for installing and running small module reactors. We specialize in developing remote tooling solutions that incorporate proven technologies and methodologies into new SMR design builds. Efficient and dependable tools are crucial for the safe operation of SMRs and advanced reactors.

Customer Challenges

Improving concept design while protecting budget and schedule.

Managing cost and schedule overruns in the building of new SMRs.

Reducing construction and installation time of prefabricated modules.

Ensuring worker safety in highly radiated environments.

Every nuclear reactor project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

Partnering with our nuclear customers, we simultaneously engineer, build, and test custom remote tooling systems and processes used in the building and operations of SMR power plants. Combining design and testing expertise with operation procedures, we help ensure SMR systems work the first time, giving teams the confidence they require.

Simultaneous Engineering

Optimize tooling by testing use cases and processes.

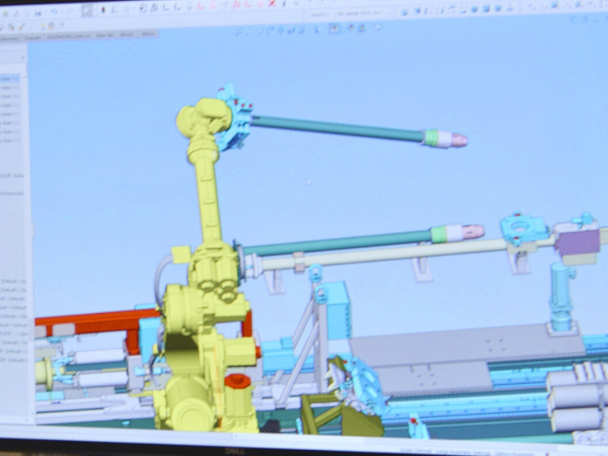

Digital Simulations

Leverage digital twin technology to model reactor design and fuel fabrication to understand the behavior of automated tooling.

Proof-of-Concept Builds

Validate tooling designs before use in the field.

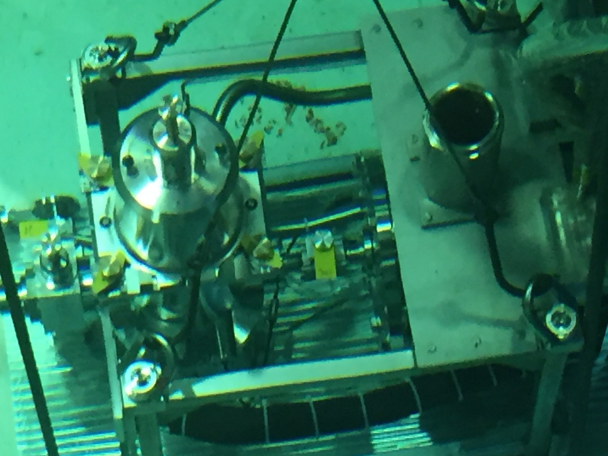

Submerge System Testing

Test small and large equipment underwater.

Training & Maintenance

Operator training and on-site experts create oversight during installation and ongoing operations.

Metrics

Develop target metrics and dashboards demonstrating potential SMR performance.

Customer Benefits

Optimize Designs

Enable teams to comprehend how designs and modifications correlate with one another early in the design process.

Stay On Budget

Avoid the expense.

Streamline System Operation

Workforce training ensures a prepared team to install and maintain equipment.

Improve Safety

Reduce human error and lowers dose exposure.

“SMR technology has the potential to provide flexible, scalable, and carbon-free energy to the grid. Together with NuScale, ATS Industrial Automation is working to advance a new generation of nuclear technology as part of a green energy future.”

Narinder Bains,

VP of Sales, ATS Industrial Automation Nuclear Division.