We are dedicated to developing assembly testing systems and validation programs that are robust, reliable, and customized to meet specific customer applications and industry requirements. With expertise across EV, automotive battery assembly, grid batteries, fuel cell, and consumer product goods, we offer test solutions, data monitoring, gauge repeatability, leak testing, start-to-final test, and more.

With 110+ battery assembly and test lines delivered, we are a proven partner for battery module and pack testing for EV and grid energy storage.

Every testing project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Testing & Management Solutions

We offer comprehensive software solutions for testing, line control, and data analysis. With Test Executive Suite, you can ensure product parts meet standards through measurement and control. Our Sequenced Automation Manufacturing Solution (SAMS) controls and verifies your lines and build process. Operators can access real-time production data, analytics, and reporting using our Reporting Analysis Line Production History (RALPH) software.

Benefits of Assembly Testing Systems

Improved Process Control

Flexible automation testing to support multiple part types.

Higher Quality Products

Identify, remove, and fix early in the process.

Minimize Warranty Claims

Protect the brand and consumer by ensuring products meet specifications reducing field failures.

Adaptable and Flexible Testing Platform

Testing software that can evolve with the business needs.

Virtual Design & Testing

Using advanced digital twin technology, our team of engineers help customers virtually simulate and emulate product designs and processes to test and optimize performance before production lines are built. Digital twin technology can be used for product design and process debugging, testing, validation, integration and operator training. Using this data, customers can refine tooling designs and assembly processes for higher return on investments, reduced risk and improved speed to market.

Testing Applications

Battery Testing

We offer in-line and end-of-line testing, including electrical functional testing, leak testing, ingress protection for liquids (IPX 6-7) and more. Our leak testing system leverages air compared to tracer gas to reduce operating costs. We can detect 10 ml. of air lost in a volume of 250,000 ml. Additionally, our modular connector design has up to 800V and 400A capability with charge and discharge capabilities and thermal monitoring. The connectors are easily maintained and help streamline testing across multiple battery form factors. Our engineering team works with battery customers to digitalize their lines to debug, optimize, and validate systems before lines are constructed.

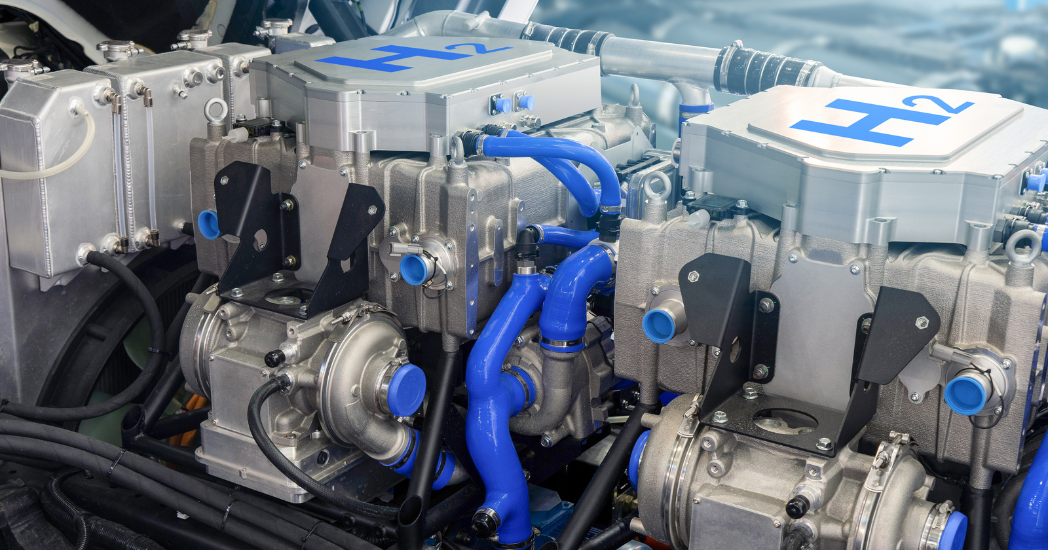

Fuel Cell Testing

We offer comprehensive testing capabilities to ensure that the fuel cells used in eMobility or energy grid storage applications meet performance and reliability while reducing the cost of market entry. Our team of experienced engineers collaborates with customers to validate manufacturing processes, making it easier to bring fuel cell manufacturing from the lab to production-ready test system. Our in-line and end-of-line cell testing capabilities include leak, seal, performance, electrical, welding, humidity, noise vibration harshness (NVH), and more.

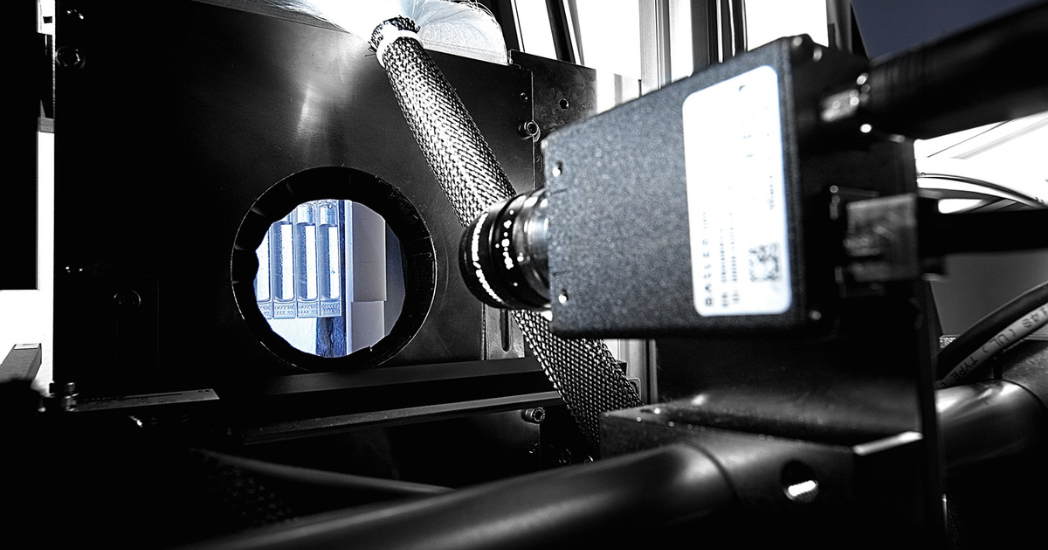

Nuclear Automation Testing

We collaborate with nuclear power plants to design and test mission-critical automated tooling used in nuclear decommissioning, refurbishment, maintenance and new builds. Services include creating virtual simulation, building physical prototypes, and conducting extensive testing.

This helps mitigate risk, optimize designs, and provide facilities with the confidence that the tooling will operate as intended.

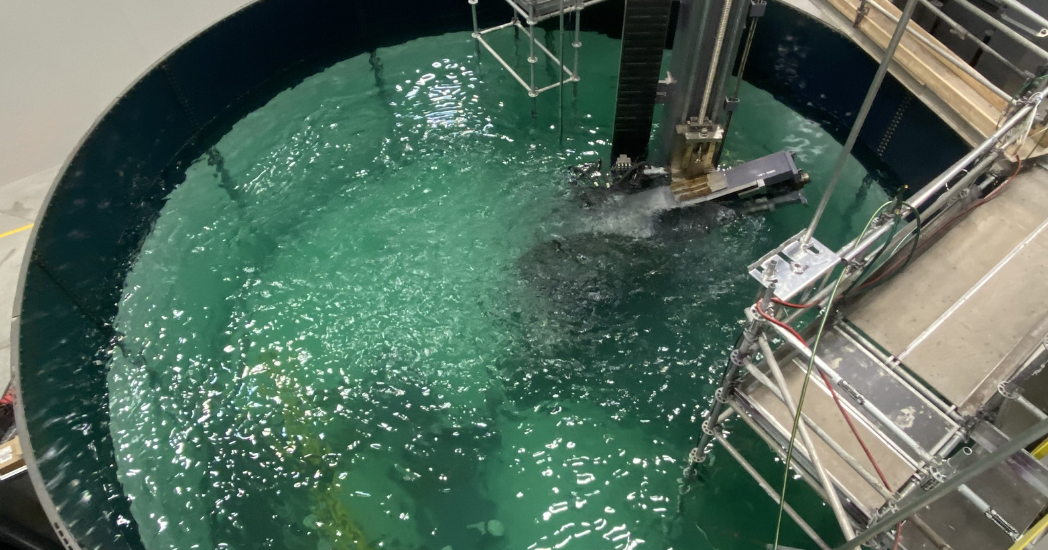

Submerged Equipment Testing

Our integrated submerged system testing and training facility features multiple pools to accommodate underwater testing of small and large nuclear equipment. Our unique approach provides greater flexibility for real-time system modifications and hands-on training without impacting project schedules or budgets. Verify that your system operates as expected in a submerged environment before it enters your nuclear facility.

This helps mitigate risk, optimize designs, and provide facilities with the confidence that the tooling will operate as intended.

Consumer Product Testing

We work with leading consumer product companies to develop assembly test systems and inspection solutions to ensure the integrity and safety of materials, parts, packaging and final assembled products. Our engineering experts design test systems that drive faster cycle time while delivering a quality product. Our robust capabilities include leak testing, seal and housing integrity, surface inspection, electrical testing, performance testing, gauge repeatability, and welding quality testing. We can customize our solutions to meet your unique product and regulatory needs.