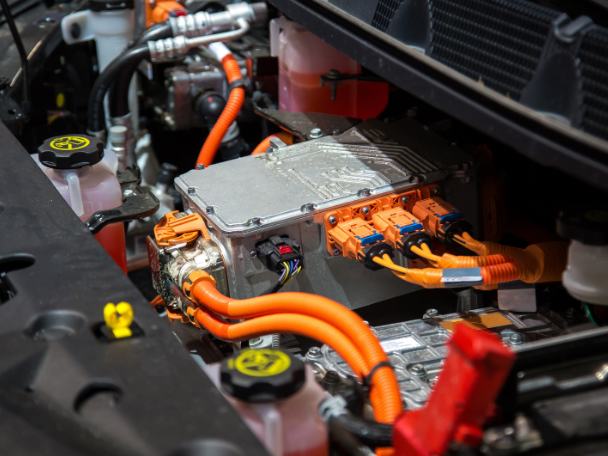

We provide automated rotor and final assembly systems for eMotors. Our approach optimizes the electric motor assembly with minimal handling, reducing errors and creating a quality product. Our proven processes, project management skills, and global reach enable customers to meet their launch dates and stay within budget.

Customer Challenges

Automating handling of heavy, compact components used in the chassis-mounted electric motor assembly.

Managing complexity of multiple components and their tolerance chain.

Repurposing and optimizing current manufacturing footprint(s) to support multiple eMotor configurations.

Ramping up eMotor production efficiently and effectively to meet the growing demand for EV manufacturing.

Every eMotor project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

Whatever the stage of your product’s life cycle — design, iteration, prototype, or full commercial production — we have the expertise, personnel, and end-to-end solutions to optimize your automated production.

Digital Engineering

Utilize digital twin to virtually validate the system’s performance before building.

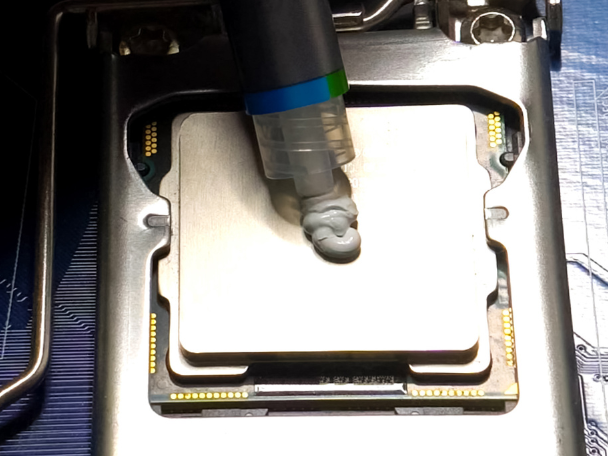

Consistent Paste Application

Automate the application of thermo paste to the stator.

Monitor & Manage Tolerances

Monitor and manage all tolerances across all stations.

Customer Network Connectivity

Connect to Manufacturing Execution Systems (MES) to manage part, quality, and traceability.

Customer Benefits

Fast Cycle Time

Scale from low cycle to production cycle time.

Tight Tolerances

Improve efficiency of the eMotor.

Minimize Risk to Supply Chain

Bring automation close to the end customer through near-shoring.

Optimized Square Footage

Do more in a smaller space.

Modular Approach

Supports multiple eMotor and power configurations.

“The team at ATS Industrial Automation are experts and truly know what they are doing. They were instrumental in helping us ramp up our eMotor assembly line.”

Large European OEM