We provide mission-critical automation and remote tooling systems for refurbishing nuclear reactors, extending its life by decades. Our experts have designed and delivered over 500 nuclear automation tooling systems that remotely remove highly irradiated reactor internals. We are a trusted partner with an exemplary record, and patent pending technology within the nuclear industry.

Reduce Time on Critical Path by up to 50%.

Customer Challenges

Shortening critical path and creating a schedule that teams can rely on.

Automating manual processes for the rapid removal, and installation of new reactor internals.

Reducing human error by standardizing training and automating operations.

Lowering operator dose and ensuring personnel safety.

Creating a reliable and repeatable process that optimizes performance.

Every nuclear refurbishment project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

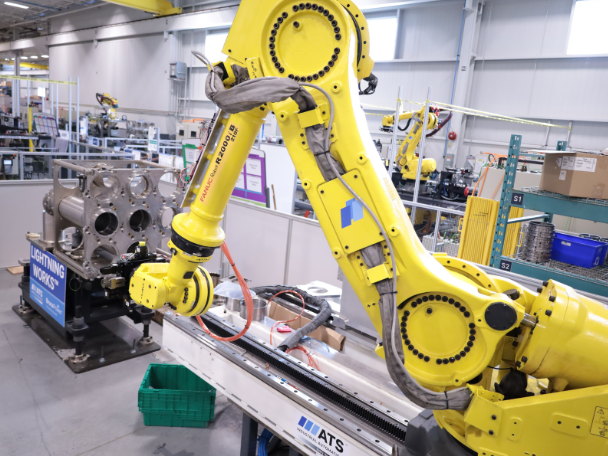

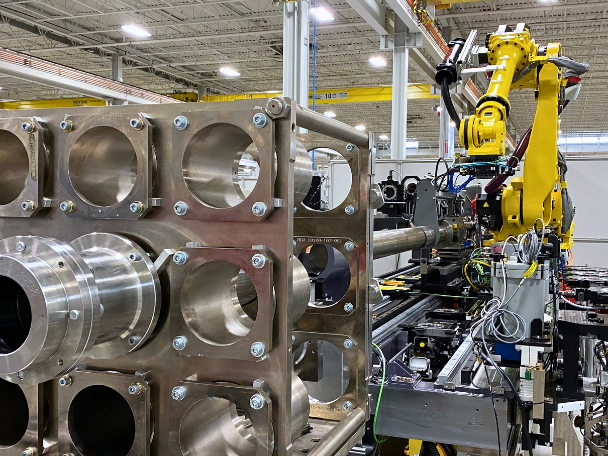

Partnering with our nuclear customers, we continuously engineer, build and test custom remote tooling systems and processes to refurbish nuclear power plants.

Automated Inspection & Fuel Channel Installation

Automating highly repeatable manual operations.

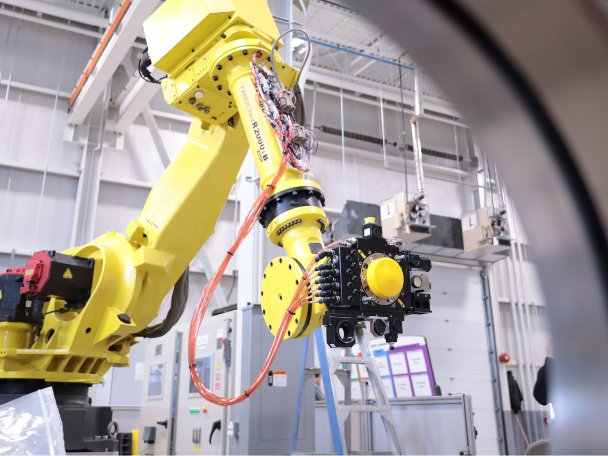

Reusable & Remote Tooling

Designed for high-risk environments and repeatable tasks.

Rapid Prototyping

Validate, troubleshoot, and optimize the design prior to the final build.

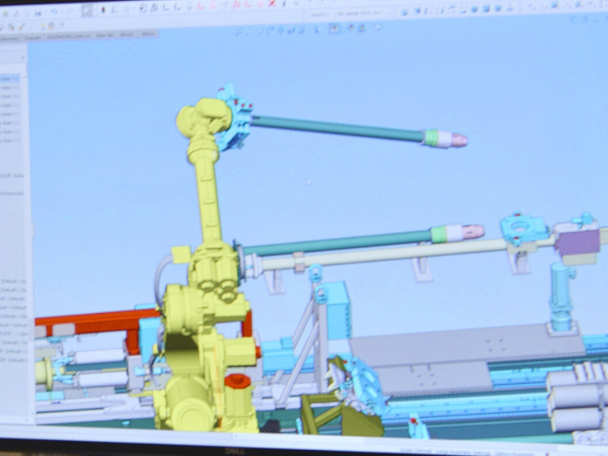

Digital Simulation & Emulation

Digitalization to verify and address any tooling and environmental risks.

Training & Service Experts

Leverage SmartCoach™ and digital twin for employee training along with on-site experts.

Nuclear Waste Storage Systems

To reduce and safe storage of nuclear waste material.

Customer Benefits

Accelerated Delivery

Using simultaneous engineering and proven methodologies.

Risk Reduction

Ensure tools and teams are properly prepared prior to deployment.

Improve Safety

Reduce human error, lower dose exposure, and objectively measure human performance.

Operational Insights

Improve performance and maintenance with data and metrics.

“For the past ten years, ATS has been a strategic partner, most recently designing, building, and integrating a new class of automation tools for reactor refurbishment. The remote capabilities and precision of ATS Industrial Automation systems will help us reach our goal of net-zero by automating and modernizing our infrastructure to improve safety, performance and efficiency.”

Eric Chassard,

Executive Vice President of Projects and Engineering at Bruce Power.