With over 45 years of automation experience, we design and build automated tooling solutions and test systems for the nuclear decommissioning, dismantling, waste handling, and volume reduction of irradiated components, systems, and equipment. Our customers gain reliable processes that reduce costly downtime, provide schedule predictability, and improve worker safety.

Customer Challenges

Automating manual processes for the rapid removal and packing of reactor internals into waste containers.

Standardize training and operations by reducing the reliance on legacy knowledge.

Ensuring worker safety in highly radiated environments.

Maintaining a predictable schedule that teams can rely on.

Every nuclear decommissioning project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Our Approach

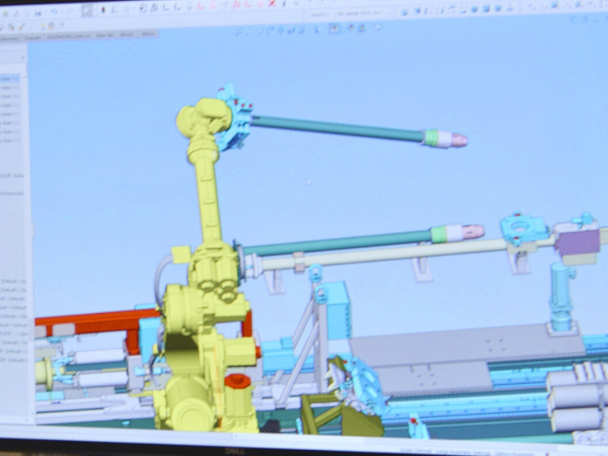

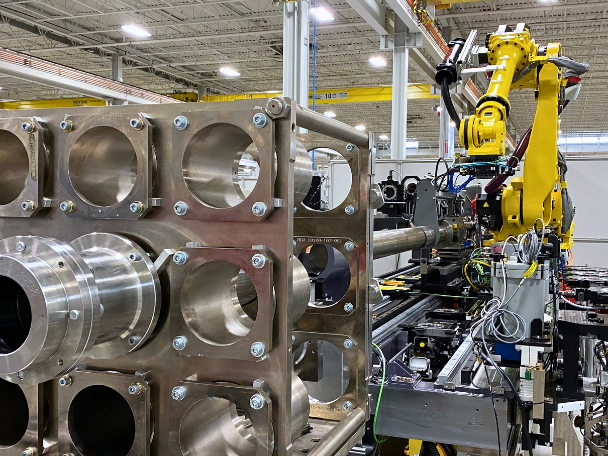

Partnering with our nuclear customers, we simultaneously engineer, build and test remote tooling systems and processes used in the decommissioning and dismantling of nuclear power plants.

Remote Material Handling

Using haptic feedback and automated motion technology to transfer radioactive material safely.

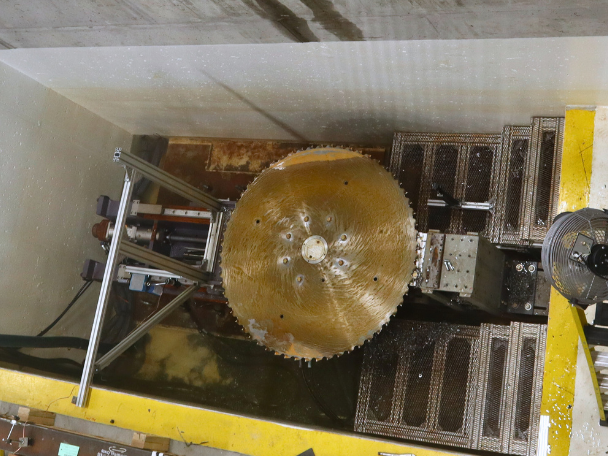

Reactor Segmentation

Identify the optimal size and cuts to efficiently remove segments.

Nuclear Waste Packaging

Optimize processing and packaging, including volume reduction of irradiated materials.

Reusable & Robust Tooling

Designed and tested for high-risk environments and repeatable tasks.

Testing & Simulation

Comprehensive testing and training leveraging realistic mock-ups and digital twin.

Nuclear Waste Storage Systems

To support the safe storage of nuclear waste material.

Customer Benefits

Accelerated Delivery

Using proven methodologies.

Scale

A partner who can take on small and large programs.

Risk Reduction

Benchmark and standardize processes.

Improve Safety

Reduce human error, and objectively measure human performance.

“We pride ourselves on being A Generation Ahead by Design… One of those needs is decommissioning, which requires the best people, planning, processes and equipment. We chose ATS to assist us because of their demonstrated nuclear industry expertise and technology, and their ability to develop a low-risk, innovative and modular solution.”

PK Chaudhary,

Holtec’s Senior Vice President of Operations.