Consumers like product variation, putting pressure on industrial and consumer product companies to ramp up manufacturing lines while maintaining the flexibility to support multiple products.

High-brand value products like tools, home goods, beauty, cosmetics, and electronics require precision, high-speed handling, and assembly to produce products consistently. As the developers of the SuperTrak CONVEYANCE™ Platform and the Symphoni™ assembly automation technology, we offer automated and modular solutions that can be easily reconfigured to assemble multiple products.

45

Years of Automation Experience.

40-1K+

Parts Per Minute.

1

Lot Size One with No Change-Over.

Every product manufacturing project is unique. Allow us to listen to your challenges and share how automation can launch your project on time.

Consumer Packaged Goods

For world brands, we deliver efficient, versatile, and reliable consumer product manufacturing solutions that reduce downtime, warranty claims, and returns. Our agile, high-speed automation technology assembles, moves, inspects, and packages your products to meet consumer demand volumes.

From health and beauty to household products and tools, we offer a range of automation solutions that address parts assembly, precision tooling, and material handling. This includes winding systems, dispensing automation, and process equipment. Our systems leverage robotics, vision, laser, conveyer, assembly, and other technologies to provide unmatched levels of performance and quality. Our approach supports your need to scale. As prototypes and productions scale, so does your business.

Logistics & Warehousing

We help e-commerce and logistics companies leverage warehouse automation systems to ramp up and streamline operations. With automated pick and sort systems using robotics, servo systems, vision, and material movement (AGV/conveyors), we help you package, label, and ship products to customers quickly.

We partner with companies to augment your unique logistics approach to scale automation solutions across dozens or hundreds of warehouses. We do this through engineering support, repeat equipment manufacturing (REM), and professional services, including installation, training, and spare part services.

With ATS Industrial Automation, you can keep your warehouses running more efficiently.

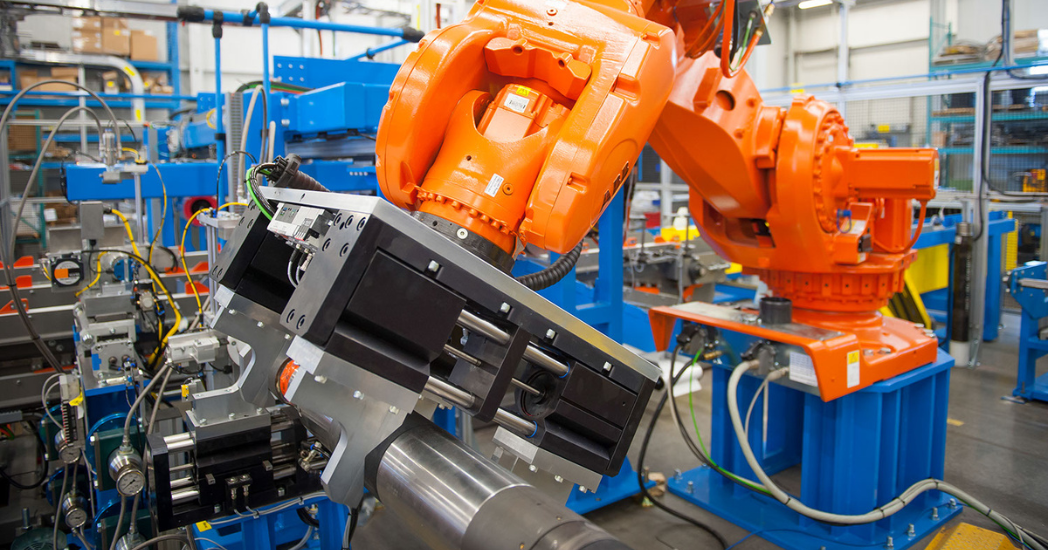

Durable Goods & Heavy Parts

The oil and gas, automotive, aerospace, solar, nuclear, and other industrial product manufacturing sectors involve the moving and joining of large and heavy components. We have extensive experience designing and implementing automated tooling for transferring, welding, or joining large parts. Our precise, high-performance systems incorporate robotics, vision, and laser processing. Automating these manual processes can improve worker safety, outputs, and yields.

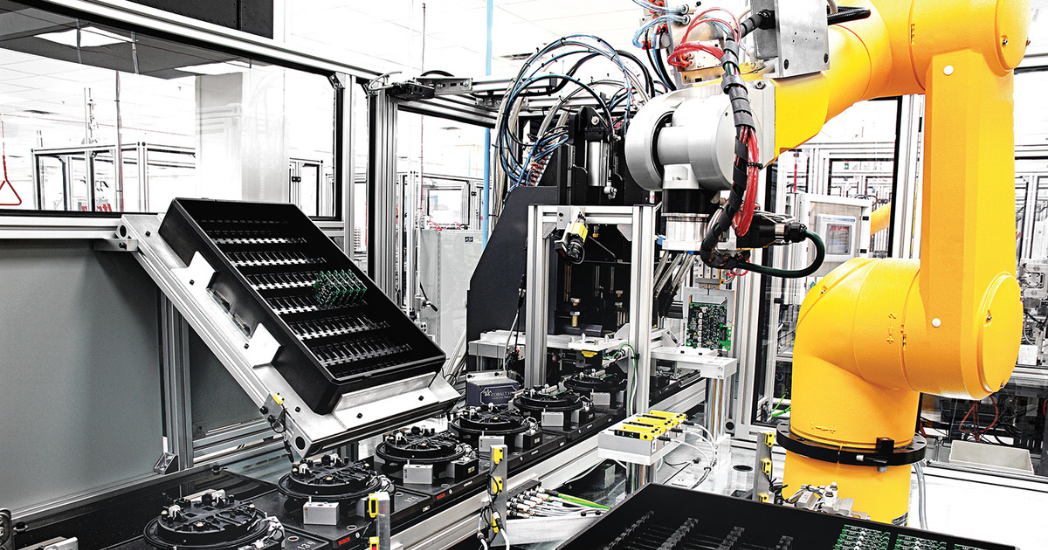

Computers & Electronics

Whether it is consumer electronics, computers or industrial electronic parts, we can design component assembly solutions tailored to your manufacturing requirements. We have teams specializing in automated high-precision assembly, vision guidance, granite tables, micron-level assembly accuracies, dispensing, material handling, soldering and Class 10 clean rooms. Our solutions are configured to your cycle times and labor environments while reflecting system designs that help ensure no defective products leave the line.