Case Studies

Filter by Category

Clear All

Quality Benefits with Automated Visual Inspection

How a partnership approach to new technology development, built on extensive industry experience, can take automation solutions to the next level....

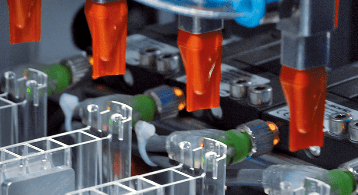

Complex Cytotoxic Syringe Assembly

Our customer, a global pharma company, is a producer of a cancer drug containing both a liquid and a powder that is delivered via syringe. Their existing assembly process was outdated, required staff in full PPE garb in cleanrooms, and was not Class A....

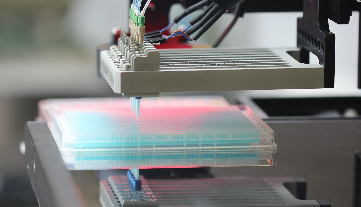

Ultra-low Dispensing for Miniaturized Diagnostics

A single modular, automated platform for miniaturized diagnostics manufacturing with integrated ultra-low dispensing technology and smart conveyance platform accelerates time to market and provides full scalability for a customer needing to scale up production....

Streamlining Automotive Parts Manufacturing through Digital Integration

A major European auto parts manufacturer faced a significant challenge. Leaders needed to optimize the production process of their automotive vacuum pumps, but space constraints meant the customer had to keep parts moving quickly to minimize downtime and operating costs. ...

Scaling Fuel Cell Testing from Sample Production to Low Volume Manufacturing

The BESS manufacturer faced a major challenge with its existing fuel cell testing system. The primary issue was the instrumentation’s obsolescence. Since many parts could no longer be serviced, this created a big risk....

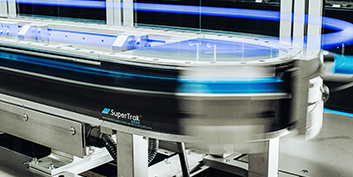

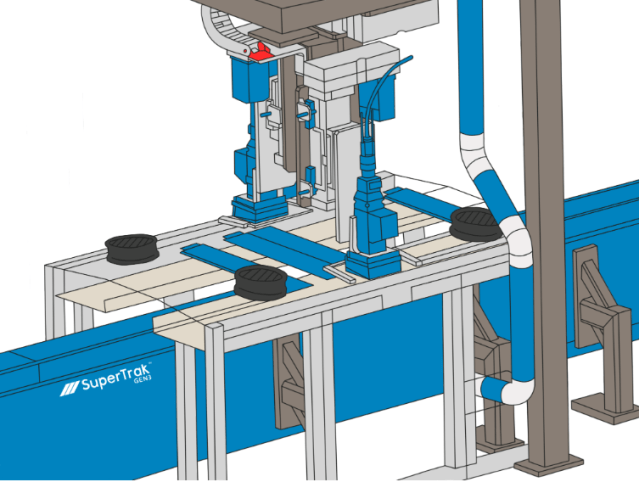

How One Manufacturing Company Gained Back Floor Space and Increased Throughput

A leading medical device manufacturer located in North America needed to increase production to keep up with market demands. After evaluating existing production processes, the decision was made to switch from traditional to smart conveyance. By utilizing SuperTrak CONVEYANCE™ during implementation, the overall system cost was reduced, and they also successfully reduced their factory footprint and increased productivity....

Using a Modular Automation Process to Scale Medical Device Manufacturing

During product development, a leading medical device manufacturer partnered with our team to implement the SuperTrak GEN3™ platform as the foundation of their automation process. While the manufacturer sought FDA approvals, they identified that SuperTrak CONVEYANCE™ could be used during early-stage process development....

Ketchup Production Line for Kraft Heinz Mexico

CFT and Heinz have worked together since the beginning of CFT’s history, in the 1950s. Our founder Camillo Catelli collaborated assiduously with the Heinz managers of that time, to innovate and expand the American tomato processing industry, in particular for the production of Tomato Ketchup. This cooperation provided a way of creating a loyal and lasting relationship between the two companies, which continues to this day....

Production And Bottling of the Musketeers Beer

Two years ago when I first received notice of a project for a new beer production and bottling plant in the north of Belgium, the idea piqued my interest straight away. We like to work on the fruition of new projects, even more so when they are in a place that is traditionally linked to the product in question....

A Single Mission: Quality of the Finished Product

From our first meeting, Fénix’s purpose with regard to its fruit processing plants has always been clear. The raw material used for the preparation of their fruit purées comes from the two separate oases of Mendoza and Rio Negro, in Argentina. The fertility of the soil, the right altitude and the climatic conditions favour the growth of a wide variety of fruit with unique aromas and flavours. As a consequence, the company needed these special characteristics to be maintained even after processing....

Frutco – Banana Processing Plant

We first met Frutco’s management during the 2015 IFU conference. Their goal was to find a reliable partner to help them enter the South American market with a banana processing plant, a business of which CFT could already boast several references and a long-standing local presence....

Reshoring Consumer Goods With Agile Automation

CPG brands have historically satisfied consumer demand for low-cost products by offshoring to low-cost labor countries. Rising costs, production delays, and supply chain breaks have made reshoring necessary....

A Leading E-Commerce Retailer Automates and Scales Their Global Fulfillment Operations

When a major e-commerce retailer was looking to finalize their prototype packaging machine and deploy these machines into production scale across their global fulfillment centers, they turned to ATS Industrial Automation...

ATS Helps a Leading Auto Manufacturer Redefine EV Battery Assembly

The automotive industry is on its way to an all-electric future, and auto manufacturers are quickly adding new electric vehicles (EVs) to their lineups....

Filter by Category

Clear All