Resources

News

Events

Enabling Automation: An Automation Podcast Series

In this monthly podcast series, join industry leaders from across ATS as they share and discuss the latest industry trends, new innovations, and more! ATS is an industry-leading automation solutions provider to many of the world’s most successful companies..

Case Studies

Quality Benefits with Automated Visual Inspection

How a partnership approach to new technology development, built on extensive industry experience, can take automation solutions to the next level....

Complex Cytotoxic Syringe Assembly

Our customer, a global pharma company, is a producer of a cancer drug containing both a liquid and a powder that is delivered via syringe. Their existing assembly process was outdated, required staff in full PPE garb in cleanrooms, and was not Class A....

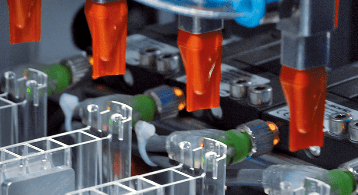

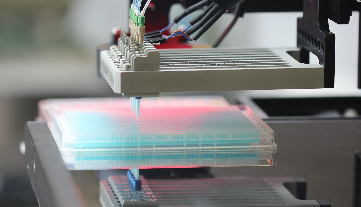

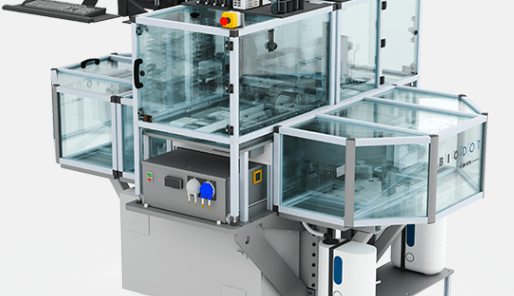

Ultra-low Dispensing for Miniaturized Diagnostics

A single modular, automated platform for miniaturized diagnostics manufacturing with integrated ultra-low dispensing technology and smart conveyance platform accelerates time to market and provides full scalability for a customer needing to scale up production....

Streamlining Automotive Parts Manufacturing through Digital Integration

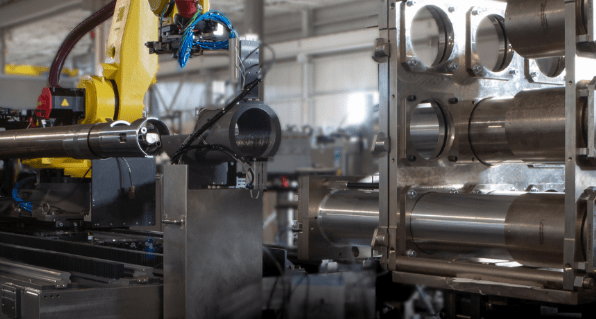

A major European auto parts manufacturer faced a significant challenge. Leaders needed to optimize the production process of their automotive vacuum pumps, but space constraints meant the customer had to keep parts moving quickly to minimize downtime and operating costs. ...

Scaling Fuel Cell Testing from Sample Production to Low Volume Manufacturing

The BESS manufacturer faced a major challenge with its existing fuel cell testing system. The primary issue was the instrumentation’s obsolescence. Since many parts could no longer be serviced, this created a big risk....

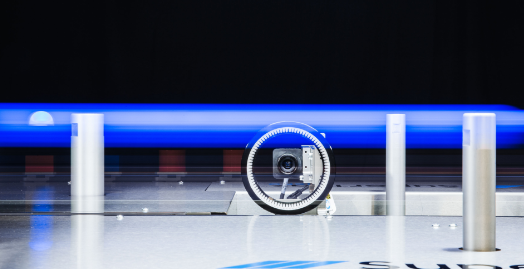

How One Manufacturing Company Gained Back Floor Space and Increased Throughput

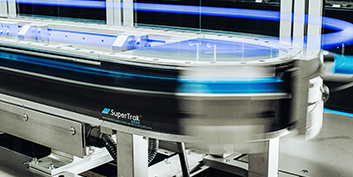

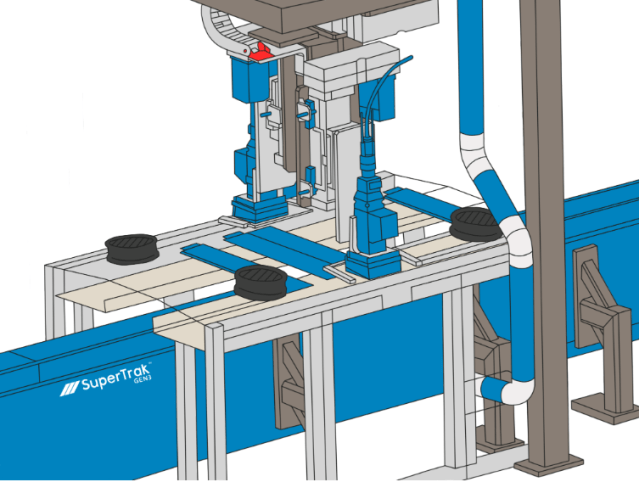

A leading medical device manufacturer located in North America needed to increase production to keep up with market demands. After evaluating existing production processes, the decision was made to switch from traditional to smart conveyance. By utilizing SuperTrak CONVEYANCE™ during implementation, the overall system cost was reduced, and they also successfully reduced their factory footprint and increased productivity....

Using a Modular Automation Process to Scale Medical Device Manufacturing

During product development, a leading medical device manufacturer partnered with our team to implement the SuperTrak GEN3™ platform as the foundation of their automation process. While the manufacturer sought FDA approvals, they identified that SuperTrak CONVEYANCE™ could be used during early-stage process development....

Ketchup Production Line for Kraft Heinz Mexico

CFT and Heinz have worked together since the beginning of CFT’s history, in the 1950s. Our founder Camillo Catelli collaborated assiduously with the Heinz managers of that time, to innovate and expand the American tomato processing industry, in particular for the production of Tomato Ketchup. This cooperation provided a way of creating a loyal and lasting relationship between the two companies, which continues to this day....

Production And Bottling of the Musketeers Beer

Two years ago when I first received notice of a project for a new beer production and bottling plant in the north of Belgium, the idea piqued my interest straight away. We like to work on the fruition of new projects, even more so when they are in a place that is traditionally linked to the product in question....

A Single Mission: Quality of the Finished Product

From our first meeting, Fénix’s purpose with regard to its fruit processing plants has always been clear. The raw material used for the preparation of their fruit purées comes from the two separate oases of Mendoza and Rio Negro, in Argentina. The fertility of the soil, the right altitude and the climatic conditions favour the growth of a wide variety of fruit with unique aromas and flavours. As a consequence, the company needed these special characteristics to be maintained even after processing....

Frutco – Banana Processing Plant

We first met Frutco’s management during the 2015 IFU conference. Their goal was to find a reliable partner to help them enter the South American market with a banana processing plant, a business of which CFT could already boast several references and a long-standing local presence....

Reshoring Consumer Goods With Agile Automation

CPG brands have historically satisfied consumer demand for low-cost products by offshoring to low-cost labor countries. Rising costs, production delays, and supply chain breaks have made reshoring necessary....

A Leading E-Commerce Retailer Automates and Scales Their Global Fulfillment Operations

When a major e-commerce retailer was looking to finalize their prototype packaging machine and deploy these machines into production scale across their global fulfillment centers, they turned to ATS Industrial Automation...

ATS Helps a Leading Auto Manufacturer Redefine EV Battery Assembly

The automotive industry is on its way to an all-electric future, and auto manufacturers are quickly adding new electric vehicles (EVs) to their lineups....

Webinars

Blog

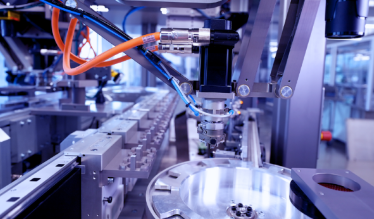

Mastering eMotor Assembly: Overcoming Challenges in the Powertrain Marriage Process

The marriage of the stator and rotor within an electric motor (eMotor) is a critical step in assembly that demands precision and careful handling. When these components are not properly integrated, several challenges and product problems can arise....

High Speed, High Stakes: Everything You Need to Know About Precision Assembly

In automation, precision isn’t just a technical specification—it’s imperative to succeed. When tolerances drop below one millimeter, the margin for error disappears. Every micron matters....

Boost Manufacturing Efficiency with Automated Assembly Tools

Automation in manufacturing is crucial for enhancing efficiency, reducing errors, and increasing throughput. By automating repetitive and complex tasks, manufacturers can achieve higher throughput and maintain consistent product quality....

The Benefits of Pre-Automation in RFQ Development: Reducing Costs and Improving Responses

Developing a request for quotation (RFQ) or request for proposal (RFP) is a critical step in procurement, serving as a formal invitation for suppliers to bid on providing goods or services....

3 Spot Checks to Know You Have the Right Technology Solution Partner

Ultra-low volume dispensing for this discussion is the ability to dispense precise single droplets that are basically invisible to the human eye and defined in units of pico or nano liter volume....

3 Ways to Enable High-Performance Automation With Less Risk

System complexities are leading to the creation of a higher functioning standard system component to enable faster project cycles. This standardization is a benefit because it provides functionality that has already been tested and verified. The function is basically accessed like a service. Now you only need to know how to use it; you do not have to invest time to understand how it works....

The Right Applications for Smart Conveyance

From simplifying tooling requirements, to quick system assemblies, to intuitive and easy integrations. Smart Conveyance provides significant value to machine builders and end-users because material costs and engineering hours can be reduced. This offers a solution that balances the overall cost of automation with market demands by allowing for reconfigurability and scalability....

What is Smart Conveyance?

Consumers demand immediacy and in order to keep up with such demands, manufacturers must rethink their production processes. Automation cells no longer can be looked upon to produce one standardized batch or product, instead, they need to be flexible and re-deployable to create shorter cycles. For manufacturers to remain competitive, engineers are being tasked with rethinking their current processes and developing ways to not only produce more, but produce more in smaller amounts of space....

A Novel Approach in Micro-Dispensing for Medtech and Consumer Diagnostic Device Manufacturing

According to a 2023 report, Global News Wire is reporting a 12.7% CAGR growth and greater than $80B USD in revenue by 2028 in Point of Care (POC) diagnostics. This tremendous growth is fueled by continuous glucose monitoring wearables, as well as the demand that was kick started with the advent of a myriad of at-home COVID-19 PCR and rapid tests....

Top 10 Ways to De-Risk Automation

Engineers know the frustration of designing a manufacturing process that is difficult to scale up or automate. Let’s say benchtop equipment was built to test an assembly process with equipment running at a slower rate to support manual loading, and the controller and servos were selected based on that rate. But when it’s scaled up, the process does not behave in the same way at the faster production rate. It may yield unrepeatable or unreliable results....

When Is the Right Time to Involve a Turnkey Contract Manufacturer?

Many OEMs/businesses have evolved out of the full lifecycle ownership mindset. Process engineering, forensic engineering, and reliability engineering are a few of the many consulting disciplines available to support and effectively problem solve where there are gaps in your product development process. Whether you retain full ownership or work with an engineering consultant to support your product development it will impact your ability to scale up for manufacturing and ultimately impact your time to market....

Are Pre-Engineered Automation and High-Speed Assembly Mutually Exclusive?

Over approximately the last 30 years, the evolution of automated systems implemented to enable advanced manufacturing has led to the proliferation of the pre-engineered automated work cell/system. In turn, this has enabled significant growth in the global deployment of automated systems throughout all facets of global manufacturing, where virtually any redundant task is automated....

How a Good Turnkey Contract Manufacturing Partner Impacts Your Business

Contract (or white label) manufacturers play a very important role when it comes to producing certain products. CMs offer technical expertise gained through years of experience in the field with respect to product design, repetitive equipment manufacturing (REM), system integration, and providing service that is highly agile and can quickly scale your business....

3 Reasons Why Sourcing a Turnkey Contract Manufacturer Will Improve Your Bottom Line

You can’t be an expert at everything. For this reason, Original Equipment Manufacturers (OEM) are constantly faced with meeting various product commercialization issues. Between streamlining supply chains, minimizing material handling, and consolidating vendor selections to remain competitive, there’s a lot that goes into improving your bottom line....

Benefits of Project Management Involvement in Sales

Do your suppliers include project management expertise when preparing your proposal? Buying custom automation equipment can be a time-consuming activity that requires extensive planning for both cost and schedule. Often these plans are tied to business needs and impact decision-making for your company at a high level, so their accuracy is critical. ...

Do’s and Don’ts When Choosing An Automation Systems Provider

Congratulations! You have decided to automate your manufacturing processes and streamline the production of your product(s). To arrive at this point, you spent critical time and effort on justifying this investment decision. Maybe you needed a solution that would support additional production capacity to satisfy customer demand, or to launch a new product, or as a result of an improvement initiative to lower your manufacturing costs....

5 Strategic Considerations for Integrating Automation in Your Medical Manufacturing

It is undeniable that automation is a powerful tool in manufacturing that can help businesses increase efficiency, reduce costs, and improve quality. It involves using various integrated technologies to automate tasks and processes that were previously done manually or by aging machinery, freeing up time and resources for more valuable activities. Given the planning and investment that comes with the decision to automate, there are some key considerations around the strategy to introduce automation....

Top 5 Medical Device Trends in 2023

As we roll out our 2023 operational plans, the medical device industry is set to witness some exciting developments and trends. Here are the top five trends to keep an eye on throughout the year:...

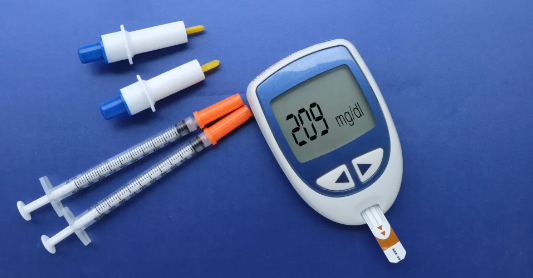

Interesting Facts About Diabetic Device Manufacturing

Survivalists say that abled bodies require a healthy supply of food, water, air, and shelter to survive. But to many diabetics, like myself, insulin must be added to the list. As a result, I’ve found that insulin dependent people are often fascinated by the technologies that replace the function of their MIA pancreata. This fascination is rivaled only by those that work in the Life Sciences and medical technology industry....

5 Steps to Improving Productivity in Pharma Manufacturing

Increased output, greater product consistency, and decreased costs are just some of the benefits of improved productivity. But knowing where to begin on your efficiency journey can be a challenge. That’s why we’ve come up with 5 Ways to Improve Productivity in Pharma Manufacturing, an easy-a-to-implement guide for achieving long-term success....

The Automated Pharmacy Made Possible by Automated Storage And Retrieval Systems (ASRS)

In pharmacies, automated storage and retrieval systems (ASRS) are gaining popularity as a result of the advantages they offer over conventional manual storage techniques. As the name implies, these systems are created to automate the storage and retrieval of objects like pharmaceuticals and other medical products....

5 Ways Pharmaceutical Manufacturers Can Improve Productivity and Quality 2023

Few industries have quality requirements as strict as those of pharma manufacturing; every part of the process must be tightly controlled. The pharma industry faces multiple challenges, with failures in product, quality, or supply chain leading the way. With expectations that drugs will be produced faster and more cheaply, how can a manufacturer be prepared for what’s on the horizon?...

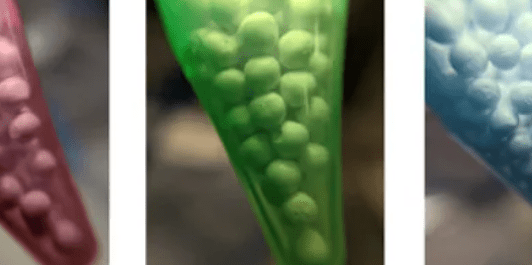

Lyobeads Are the Hottest Thing in Freeze Drying For Pharma

Lyophilization is basically a freeze-drying process that removes water from a product after it is frozen and placed under a vacuum, producing a soft powder, sometimes referred to as a cake. If we take that process and apply it to a single droplet of liquid, we are creating a lyo ‘bead’ rather than a lyo ‘cake’. Lyobeads are an excellent alternative to the traditional cakes...

5 Biggest Mistakes Made When Designing a Product – 2023

It’s tough out there and the competition is fierce, no matter what industry you’re in or what product you’re introducing to meet a need – or create one. It’s a universal rule that whoever gets to market first gets the lion’s share, so there’s plenty of pressure to make each of your 24 hours a day work that much harder. But another rule says you can choose only two of good, cheap or fast....

3 Steps to Reducing Manufacturing Costs Through Automation

To increase profit you can either sell at a higher price or cut the cost of production. Easy, right? When conventional responses don’t address modern and complex issues it’s time to consider new approaches....

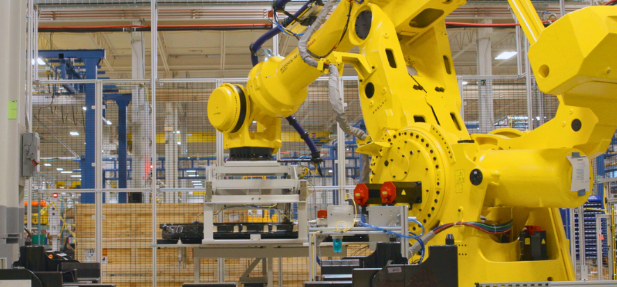

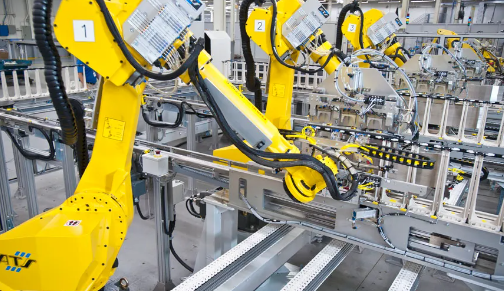

Robotic Tray Handling and Palletizing – Integration or Automation

It is common for manufacturers to look for efficiencies in their lines based on linear access; but more often manufacturers today are interested in the potential of robotics because they can either be integrated into existing lines or be built as an end-to-end solution. ...