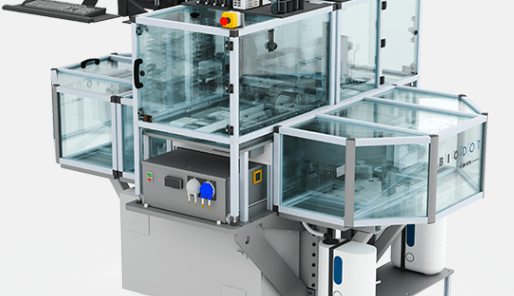

Ultra-low volume dispensing for this discussion is the ability to dispense precise single droplets that are basically invisible to the human eye and defined in units of pico or nano liter volume….

3 Spot Checks to Know You Have the Right Technology Solution Partner