With broad and in-depth knowledge from across multiple industries and technical fields, ATS delivers single-source solutions to customers that lower their production costs, accelerate delivery of their products and improve quality control. We engage with our customers on both greenfield programs, such as equipping new factories, and brownfield programs, such as capacity expansions, line moves, equipment upgrades, software upgrades, efficiency improvements and factory optimization.

Full Service Offering

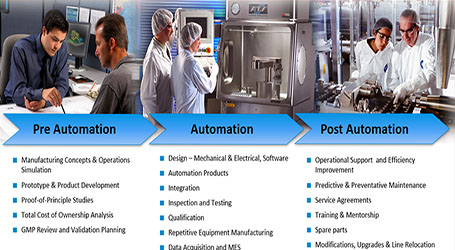

We have been helping customers around the world transform, streamline and optimize their manufacturing operations since 1978. From planning and justifying a program to designing, building, and commissioning an automation solution to after sales and services and ultimately retirement of an asset, ATS has been there to assist customers with asset life cycle management.

Pre-Automation Services

Perfecting automation requires the right combination of vision and due diligence. Drawing upon a broad technical base and seasoned experience with multiple markets, our experts develop optimized manufacturing strategies that consider everything from process design and time to market, to unit cost and maximum return on investment. Through close collaboration with customers and disciplined data-driven analysis, we conceptualize, simulate and perfect comprehensive solutions – before you invest.

DigitalizationAutomation & Integration Services

For customers that have decided to proceed with an automation project, ATS offers specialized equipment for specific applications and markets, as well as a number of automation and integration services, including engineering design, prototyping, process verification, specification writing, software and manufacturing process controls development, equipment design and build, standard automation products/platforms, third-party equipment qualification, procurement and integration, automation system installation, product line commission, validation and documentation. Duplicate or repeat builds of systems is not uncommon, leveraging the design and lessons learned from the original system.

AutomationPost-Automation Services

Our pro-active team helps ensure automated manufacturing stays up and running – with such single-source solutions as remote diagnostics, critical analysis, preventive maintenance, multi-language documentation and hassle-free spare parts. We work closely with customers to ensure their personnel have the proper skills to run systems safely, efficiently and sustainable, and we give them real-time insight into their operations through Illuminate™. And when the time comes to upgrade, retrofit or move a system, we’re there for that too. See Services > After Sales and Services for more information.